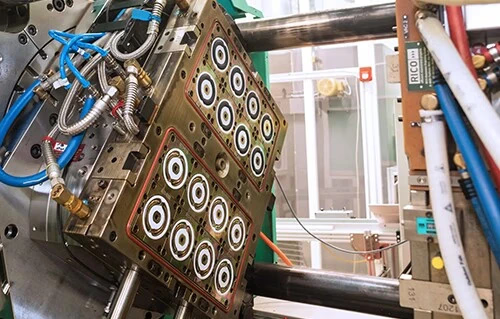

Custom Injection Molding Service

Start A New Injection Molding Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

Injection Molding Processes

Transition seamlessly from prototyping to on-demand manufacturing for affordable, high-quality molded parts in just a few days. Even better, your prototyping tool becomes free when you switch to an on-demand manufacturing tool. Partnering with a single supplier that offers free design consultation significantly accelerates the production process, enhancing supply chain flexibility, ensuring more consistent parts, and simplifying the qualification process.

Insert Molding is a manufacturing process in which resin is heated in a barrel until it reaches a molten state, then injected into a mold to create a final, production-grade thermoplastic part.

Liquid silicone rubber (LSR) molding is a thermoset process where a two-component compound is mixed and then heat-cured in the mold using a platinum catalyst to produce the final part.

Overmolding and insert molding are two-part injection molding processes in which one material is applied over a second substrate or metal insert, forming a single integrated component.

Micro molding produces minute, intricate plastic components through injection molding, serving industries like electronics, medical devices, and micro-mechanics.

Injection Molding Materials

We have wide selection of more than 100 thermoplastic and thermoset materials.

Thermoplastics

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic polymer known for its toughness, rigidity, and impact resistance. It’s widely used in a variety of applications, including automotive parts, consumer electronics, toys (like LEGO bricks), and 3D printing.

Subtypes

- ABS Beige(Natural)

- ABS Black

- ABS Black Antistatic

- ABS Milky White

- ABS+PC Black

- ABS+PC White

PA (Nylon) is a versatile synthetic polymer known for its high strength, toughness, and excellent chemical and wear resistance, commonly used in textiles, automotive components, and industrial applications.

Subtypes:

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige(Natural)

- PA66 (Nylon) Black

PE (Polyethylene) is a lightweight, durable, and versatile thermoplastic widely used in packaging, containers, and plastic bags due to its excellent chemical resistance and flexibility.

Subtypes:

- PE Black

- PE White

PEEK (Polyether Ether Ketone) is a high-performance engineering thermoplastic known for its exceptional mechanical strength, chemical resistance, and thermal stability, making it ideal for demanding applications in aerospace, medical devices, and industrial components.

Subtypes:

- PEEK Beige(Natural)

- PEEK Black

PMMA (Acrylic) is a transparent thermoplastic known for its excellent optical clarity, weather resistance, and shatter resistance, commonly used as a lightweight and durable alternative to glass in applications like windows, lenses, and displays.

Subtypes:

- PMMA Black

- PMMA Transparent

- PMMA White

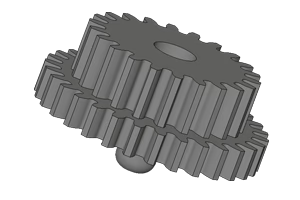

POM (Polyoxymethylene) is a strong, stiff engineering thermoplastic with low friction and excellent dimensional stability, commonly used in precision parts like gears, bearings, and fasteners.

Subtypes:

- Dark brown (coffee) POM 100AF

- POM Black

- POM Blue

- POM White

PP (Polypropylene) is a versatile, lightweight thermoplastic known for its high chemical resistance, toughness, and flexibility, commonly used in packaging, automotive components, and textiles.

Subtypes:

- PP Black

- PP White

- PP+GF30 Black

HDPE (High-Density Polyethylene) is a strong, durable thermoplastic with excellent chemical resistance and high impact strength, widely used in products like pipes, bottles, and plastic containers.

Subtypes:

- HDPE Black

- HDPE White

- LDPE White

PBT (Polybutylene Terephthalate) is a strong, durable thermoplastic with excellent electrical insulation properties, chemical resistance, and dimensional stability, commonly used in automotive parts, electronics, and household appliances.

Subtypes:

- PBT Black

- PBT Milky White(Natural)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Thermosets

- Standard silicone (30, 40, 50, 60, and 70 durometers)

- Medical-grade silicone

- Optical-grade silicone

- Fluorosilicone (fuel and oil resistant)

Surface Finish Options

We offer a variety of high-level surface finishes and only some common finishing options are listed as below. There are more finish options for custom injection molding parts.

Painting

Applying a protective or functional coating to surfaces. It involves the application of liquid paint and then undergoes a curing process to solidify the paint film.

Silk Screen

Applying images, patterns, or text to surfaces.

Laser Marking

Labeling, engraving, or adding information to materials. It involves using a laser beam to alter the surface of the workpiece, creating visible marks without physical contact.

Advantages of Injection Molding

Injection molding is plastic manufacturing process that can produce high quality parts at scale. It’s typically used for low- to high-volume production but our aluminum tooling can also make prototyping runs economical.

- Low cost at higher volumes

- Exceptional part cosmetics and surface finish

- Repeatable

- Complex parts

- Low scrap rate

- Large selection of thermoplastic and thermoset materials

Why Choose Us for Custom Injection Molding?

Unmatched Lead Times

Cut weeks—or even months—off your product development cycle and bridge to production faster with injection-molded parts, some of which can ship in as little as 1 day.

Design for Manufacturing Support

Every quote includes instant pricing and design feedback. We analyze your 3D CAD files to spot potential issues during molding, such as hard-to-machine undercuts or insufficient draft.

No Minimum Order Quantities (MOQs)

Order exactly what you need, when you need it. With no MOQs, you can flexibly manage market shifts, address demand fluctuations, and source parts efficiently for bridge production, emergencies, or product customization.

Injection Molding Expertise

From prototype to production, we’re with you every step of the way, offering finishing options and inspection reporting to ensure a smooth transition to full-scale production.

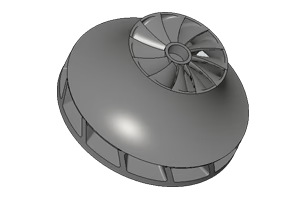

Multi-industry applications of Injection Molding services

We’ve manufactured millions of parts for a wide range of applications, with specialized expertise in such as automotive, medical devices, electronics, consumer products, etc.]. Our deep knowledge in these sectors allows us to deliver high-quality, tailored solutions for every project.

Aerospace

Precision manufacturing boosts aerospace development.

Automotive

Automotive grade certified precision parts.

Consumer Products

First choice for new product launches

Medical

Medical grade certified precision parts

Robotics

Accelerate the development of the future robotics industny

Injection Molding FAQs

Yes, we offer a production tooling option called on-demand manufacturing. This tooling option provides several benefits: lower piece part price, multi-cavity capabilities, guaranteed tooling for the life of the project (we will cut a new tool if it wears out), and first article inspections.

In most cases, we can maintain a machining tolerance of +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm).

Let’s Build Something Great, Together