Custom CNC Milling Services

Start A New CNC Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

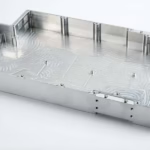

HYmoldplastic’s CNC Milling Service

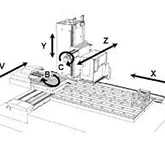

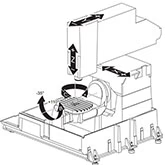

3 Axis CNC Milling

- Suggest Industry Application:

- Industrial Equipment

- Consumer Products Industry

- Electronics Industry

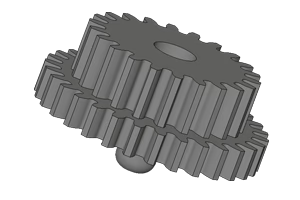

4 Axis CNC Milling

- Suggest Industry Application:

- Automotive CNC milling

- Medical CNC Machining

- Communication

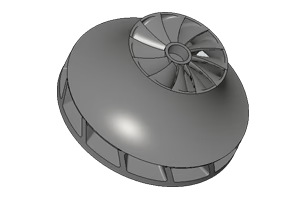

5 Axis CNC Milling

- Suggest Industry Application:

- Aerospace

- Robotics

- Semiconductor

What is CNC Milling?

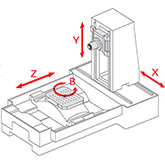

CNC milling uses rotational cutting tools to remove material from a workpiece to produce finished parts and products. This manufacturing process works well for many materials, including metals, polymers, wood and glass. CNC milling systems generally have 3 linear degrees of freedom: the X, Y and Z axis. This allows for top-notch precision and detailing. HYmoldplastic also offers more advanced, 5-degree systems, where the tool head and machining bed (A and B axis) can also rotate. 5-axis CNC machines can produce parts with high geometric complexity without needing multiple machine setups.

Our Custom CNC Milling Capabilities

Parameter | Specification |

Part Size | 2000 mm x 1500 mm x 300 mm |

Minimum Wall Thickness | 0.8 mm (metals), 1.5 mm (plastics) |

Linear Tolerances | ±0.0002” (0.005 mm) |

Minimum Feature Size | 0.5 mm or Ø 0.50 mm |

Minimum Cutting Depth | 0.3 mm |

Cavity Depth | 4x width (w) |

As Machined Finish | Ra 125 or better |

Undercut Width (T-slot) | 3-40 mm |

Complex Features | Curved surfaces, undercuts, deep cavities, grooves, complex contours, asymmetrical features, etc. |

CNC Milling Material Options

Online CNC machining services can deal with various materials, each having unique properties that make them well-suited for a broad range of materials.

CNC Metal

It is a light, non-reactive metal, hence a favorite option for aerospace and auto parts manufacturing.

Alloys

- Aluminum 6061, 6061-T6

- Aluminum 2024

- Aluminum 5052

- Aluminum 5083

- Aluminum 6063

- Aluminum 6082

- Aluminum 7075, 7075-T6

- Aluminum ADC12 (A380)

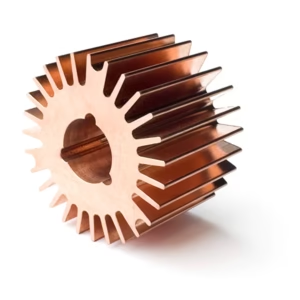

A metal with high electrical conductivity and flexibility that is commonly used for the composition of electric elements.

Alloys

- Copper C101(T2)

- Copper C103(T1)

- Copper C103(TU2)

- Copper C110(TU0)

- Beryllium Copper

Made by combining copper with zinc, brass is easy to shape into molds and pleasingly attractive.

Alloys

- Brass C27400

- Brass C28000

- Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

- Tin Bronze

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloys

- Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

- Die steel

- Alloy steel

- Chisel tool steel

- Spring steel

- High speed steel

- Cold rolled steel

- Bearing steel

- SPCC

Stainless steel offer excellent corrosion resistance, high strength, and good machinability, making them ideal for a wide range of applications in various industries.

Alloys

- Stainless Steel SUS201

- Stainless Steel SUS303

- Stainless Steel SUS 304

- Stainless Steel SUS316 / 316L

- Stainless Steel SUS420

- Stainless Steel SUS430

- Stainless Steel SUS431

- Stainless Steel SUS440C

- Stainless Steel SUS630/17-4PH

Very light, commonly found in aerospace or automotive applications.

Alloys

- Mangnesium Alloy AZ31B

- Mangnesium Alloy AZ91D

This element combines lightweight and high tensile strength and is hence utilized in aircraft construction alongside dental implants.

Alloys

- Titanium Alloy TA1

- Titanium Alloy TA2

- Titanium Alloy

- TC4/Ti-6AI 4V

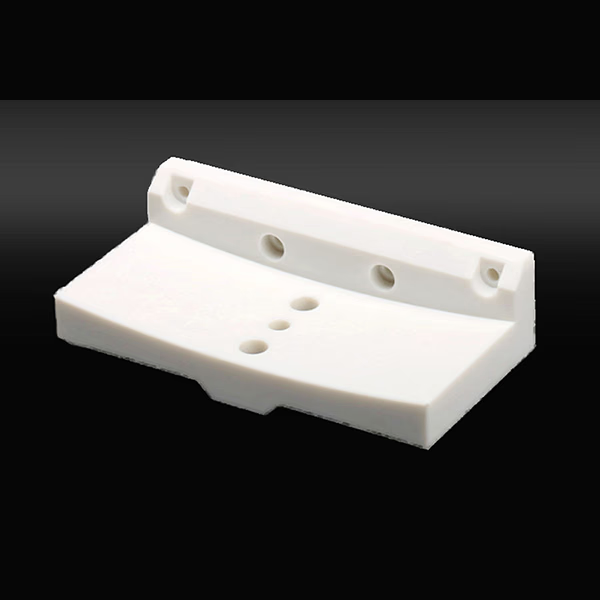

CNC Plastics

Its strength, impact resistance, and ease of machining, making it suitable for prototypes, enclosures, and consumer products.

Subtypes

- ABS Beige(Natural)

- ABS Black ABS

- Black Antistatic

- ABS Milky White

- ABS+PC Black

- ABS+PC White

Their high strength, flexibility, excellent wear resistance, and low friction properties, making them ideal for producing durable and reliable parts.

Subtypes

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige(Natural)

- PA66 (Nylon) Black

This plastic has excellent mechanical properties; thus, it is called high-performance plastic.

Subtypes

- PAI Brown

Polycarbonate (PC) is a durable, transparent thermoplastic used in CNC machining for its high impact resistance, optical clarity, and good dimensional stability, making it ideal for applications like protective covers, lenses, and medical devices.

Subtypes

- PC Black

- PC Transparent

- PC White

- PC Yellowish White

- PC+GF30 Black

PE (Polyethylene) materials for CNC machining are appreciated for their excellent chemical resistance, low moisture absorption, and high impact strength.

Subtypes

- PE Black

- PE White

Its strength, impact resistance, and ease of machining, making it suitable for prototypes, enclosures, and consumer products.

Subtypes

- ABS Beige(Natural)

- ABS Black ABS

- Black Antistatic

- ABS Milky White

- ABS+PC Black

- ABS+PC White

It is A hard and strong resin used predominantly for bottles and food containers.

Subtypes

- PET Black

- PET White

- PET+GF30 Black

- PET+GF30 White

Clear and resists weathering, often used for optical purposes.

Subtypes

- PMMA Black

- PMMA Transparent

- PMMA White

HDPE material is widely used for its high strength, impact resistance, chemical resistance, and ease of machining.

Subtypes

- HDPE Black

- HDPE White

HIPS (High Impact Polystyrene) is an impact-resistant, cost-effective thermoplastic used in packaging, consumer products, and automotive components.

Subtypes

- HDPE Black

Polyformaldehyde (POM) has the characteristics of high stiffness, low friction, good dimensional stability, good wear resistance and so on.

Subtypes

- Dark brown (coffee) POM 100AF

- POM Black

- POM Blue

- POM White

PP has good chemical resistance; at room temperatures, PP can be flexible.

Subtypes

- PP Black

- PP White

- PP+GF30 Black

For Example: High Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics.

Custom Sourced Materials

CNC Milling Surface Finishes

Surface finishes are crucial for achieving the desired functional or aesthetic quality of CNC machined components. At HYmoldplastic, we offer a spectrum of surface finishes to enhance your parts’ function by improving hardness, roughness, corrosion and heat resistance.

Image

Name

Applicable Materials

Colors

Description

As Machined

Metals,Plastics

N/a

Anodizing

Metals

Clear, black, grey, red, blue, gold

Anodizing is a surface treatment for metal parts that improves corrosion resistance and surface hardness. It is widely used in industries such as aerospace, automotive, construction, electronics, and home furnishings.

Black oxide

Metals

N/a

Brushed

Metals

N/a

Bead Blast

Metals,Plastics

N/a

Powder Coating

Metals,Plastics

Applicable to all colors-Matt

Powder coat - Matt

Metals

Applicable to all colors-High gloss

Polishing

Metals

N/a

Electropolish

Metals

N/a

This process involves removing a material layer from a metal surface by electrochemical means. It improves smoothness and corrosion resistance. It’s mostly used on stainless steel.

Tumbling

Metals

N/a

Alodine

Metals

N/a

*Additional finishing options include chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. For materials not listed here, please contact us directly.

Multi-industry applications of CNC Milling services

Aerospace

Precision manufacturing boosts aerospace development.

Automotive

Automotive grade certified precision parts.

Consumer Products

First choice for new product launches

Medical

Medical grade certified precision parts

Robotics

Accelerate the development of the future robotics industny

Let’s Build Something Great, Together