High-quality surface finishing services enhance both the aesthetics and functionality of your parts, no matter the manufacturing process. From metals and composites to plastics, we provide exceptional finishing solutions to help you turn your envisioned prototypes or components into reality.

Name

Image

Used Materials

Color

Discriptions

CNC machining

N/A

Aluminum,

Copper,

Magnesium

Clear,

Yellow

Aluminum,

Titanium,

Magnesium

Clear, Yellow,

Green, Blue,

Black, Orange,

Purple, Red

Alodine is a chemical coating. Used to passivate and protect the workpiece from corrosion. Alodine is widely used in chemical industries such as electroplating, welding, alloy manufacturing, pigments, and leather making.

All Materials

Clear, Yellow,

Green, Blue,

Black, Orange,

Purple, Red

Fix the product to be sprayed on the rotating bracket, and then lock the bracket on the assembly line. Spray the paint evenly on the surface of the product. It gives a good touch feel onto the product, but is easy to scratch.

Black oxide is also an oxide film. Mainly used to increase the corrosion resistance and appearance of the product, and to minimize light reflection. Suitable for surface treatment of steel and stainless steel products.

ABS, Aluminum, Brass, Stainless Steel, Steel

N/A

Brushing is a surface treatment method that forms lines on the surface of the workpiece by grinding the product to achieve a decorative effect. Make the product more beautiful.

Chrome

Both laser engraving and etching uses high heat from the laser beam to leave a permanent marking on the plastic part surface. The engraving creates deep marks by removing the material, whereas the etching is using high heat to melt the material.

Aluminum, Stainless Steel, Steel, Brass, Copper

N/A

ABS, PP,PC, Nylon,PE, PET

N/A

Powder coating is a process of applying dry powder coating to metal surfaces. Powder coatings are usually applied electrostatically and then cured under heating or ultraviolet light.

N/A

N/A

Silk Screening is a printing technique that transforms a 2d image onto a 3D image. Normally a screen printing plate is made by a photochemical process. It uses the mesh to transfer the ink to the substrate.

ABS, PP,

PC, PE,

Nylon

N/A

UV coating is short for ultraviolet coating, The UV Coating is a similar process to Painting, where clean components are evenly spread with paint and are instantly dried by ultraviolet light. this gives advantages of scratch, wear, and chemical resistance.

N/A

SPI Finish standardizes surface textures on plastic parts, offering finishes from high-gloss to matte, ensuring consistent aesthetics and functionality in injection molding.

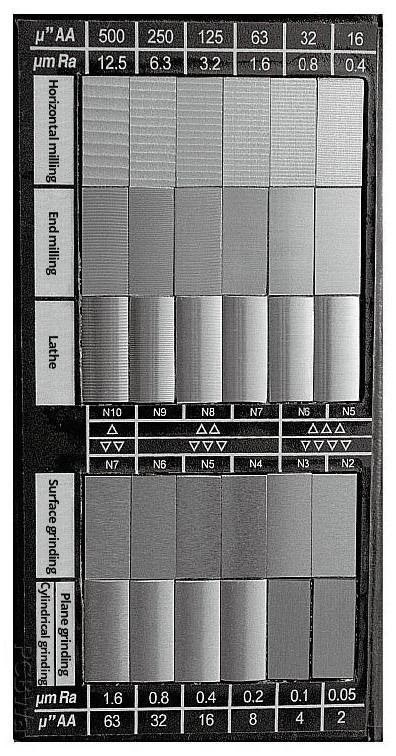

Surface roughness refers to the fine irregularities present on a surface, characterized by small peaks and valleys with short spacing. The distance between consecutive peaks or valleys (wave distance) is typically less than 1 mm, making it a microscopic geometric error. A lower surface roughness value indicates a smoother surface.

Surface roughness is primarily determined by the machining method and other contributing factors, such as:

Friction between the cutting tool and the workpiece during machining.

Plastic deformation of the material on the surface as chips are removed.

High-frequency vibrations in the machining system.

Different machining techniques and workpiece materials result in varying depths, densities, shapes, and textures of the traces left on the surface.

Surface roughness significantly affects the performance and reliability of mechanical parts, influencing:

Mating properties.

Wear resistance.

Fatigue strength.

Contact stiffness.

Vibration and noise levels.

These factors collectively impact the service life and reliability of mechanical components. Surface roughness is commonly quantified and specified using the Ra parameter.

Dongguan Hangyi Electronic Technology Co., Ltd.

Capabilities

Solutions

Industries

Company

Copyright © 2025 Dongguan Hangyi Electronic Technology Co., Ltd.