Quality Assurance at HYmoldplastic Network

We Ensure Quality in Every Step

Step 01

Pre-Production

Technical assessment

Before the production stage begins, our engineering team performs a technical assessment of your parts design. This includes an assessment on important factors such as material, surface finish, structure, process, and other details of your 3D and 2D drawings.

Material verification

On our customer’s request, we provide a certification of the material we used for making your parts. The report comes from the raw material manufacturer and usually includes material heat number, material grade, material dimensions, mechanical properties, chemical analysis, etc.

Step 02

In-Production

On-site inspection system

In-process quality control

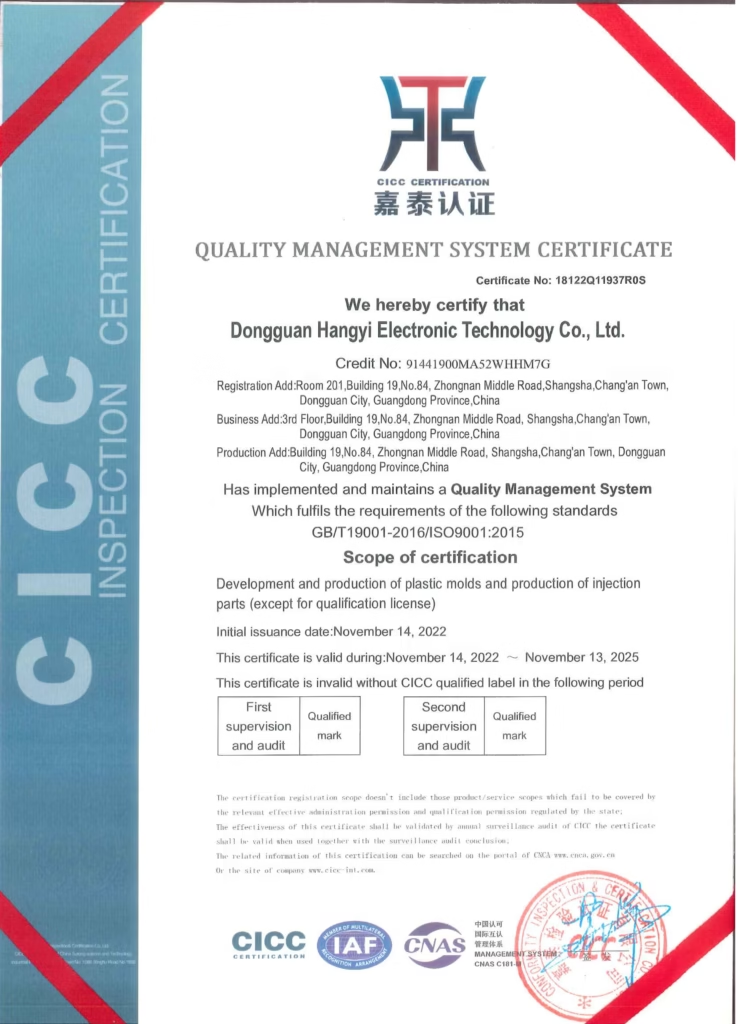

At HYmoldplastic, we strictly obey the ISO9001:2015 requirements. The quality control staff conducts routine inspections for all parts that are being produced every 2 hours. This further prevents risks from happening.

Step 03

Final-Production

Full-dimensional inspection report

Packaging

Ensuring that the parts we manufacture are of the highest quality is important. We know about the unpredictability of logistics. Therefore, we make sure we lower the risk to the parts during our packaging process. Four layers of protection: 1. wrapping paper 2. EPE 3. foam 4. paper/wooden box are applied during the packaging process, ensuring that we deliver the most high-quality and beautiful parts to you.

Manufacturing Standards

CNC Machining Manufacturing Standards

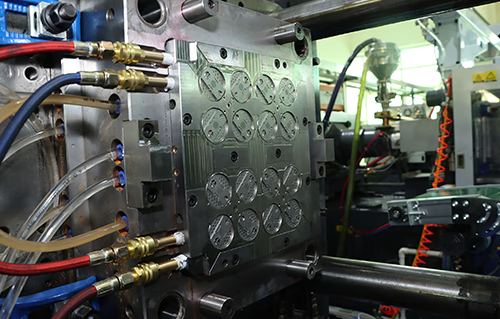

Injection Molding Standards

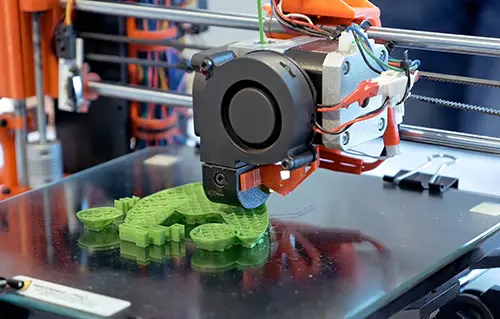

3D Printing Manufacturing Standards

At HYmoldplastic, our state-of-the-art facilities are equipped with advanced tools and technology. Our skilled team operates CNC machines, high-capacity injection molding equipment (up to 830 tons), laser cutters, benders, welders, and modern 3D printers, among other machinery. With automated production lines, we ensure precision and efficiency in every product we create.

By managing manufacturing entirely in-house, we maintain strict quality control at every stage. This approach enables us to uphold high standards, offer flexible production schedules, and deliver cost-effective solutions without compromising quality. Direct oversight minimizes risks and enhances the reliability of your supply chain.

Self-Owned Factories and Manufacturing Network

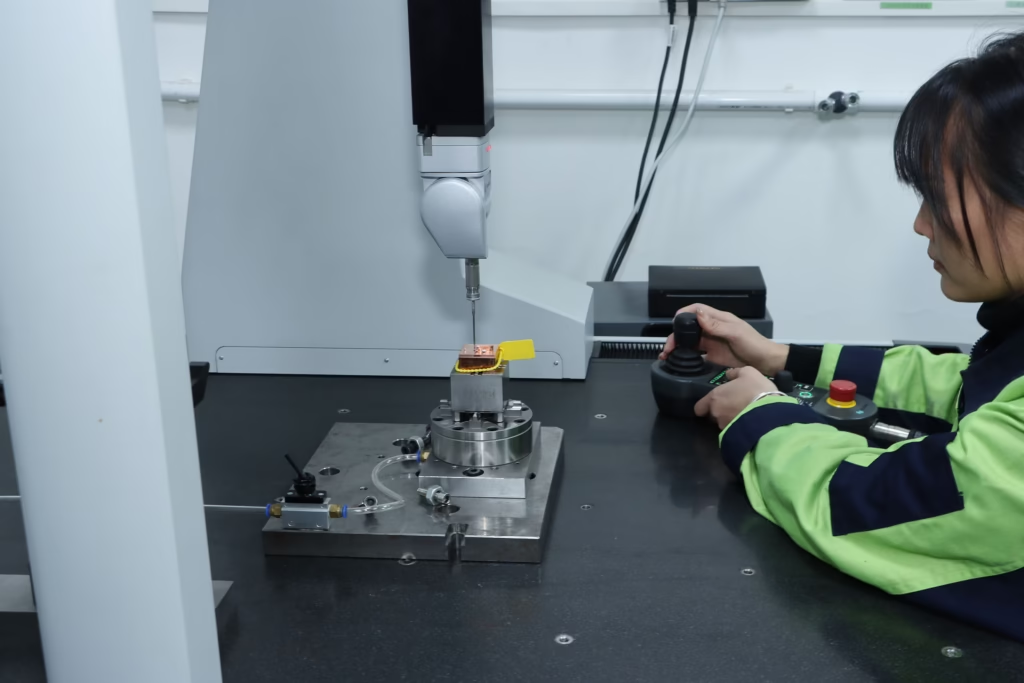

Inspection Equipment

Our facilities are outfitted with advanced inspection equipment. We conduct thorough inspections at every production stage, ensuring that every component is manufactured accurately to your specifications.

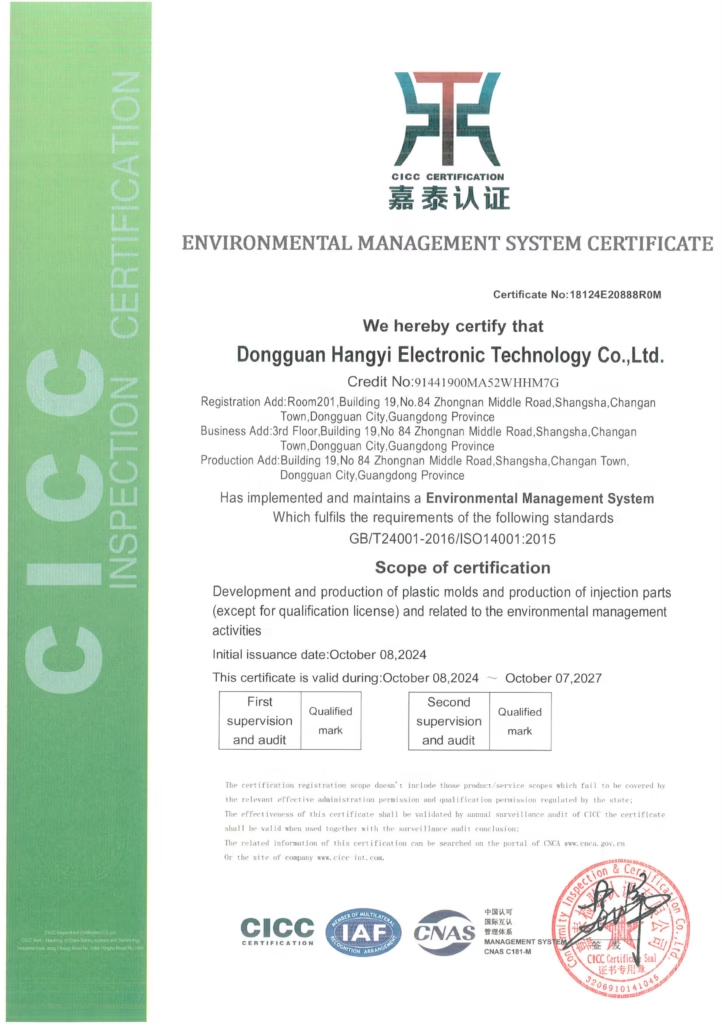

Certifications

Quality Of Documentation

We provide comprehensive quality documentation for all projects, including inspection reports, material certifications, and compliance documentation.

Visual Inspection and Testing

We ensure that each product meets the customer’s requirements for color, texture and overall appearance.

Dimensional Inspection

We use vernier calipers, micro calipers and height gauges for simple structures and CMM machines for complex products to ensure accurate measurements.

Performance Check

We evaluate component functionality to ensure that parts such as threaded holes fit properly during assembly.

First Article Inspection

We provide a final inspection report detailing all inspection procedures and results.

RoHS Reporting

We can provide a RoHS report upon request. This report confirms that a material complies with RoHS standards.

Let’s Build Something Great, Together