High Precision Automotive Parts, to Your Specifications

Why Aerospace Companies Choose HYmoldplastic

Strong Production Capability

We have established a manufacturing network of over 10,000 manufacturers with wide-ranging capabilities and certifications. Strict NDA agreements with our network protect your privacy.

Instant Quote Engine

Upload your CAD file, select manufacturing options, get an instant quote and place an order within just a few steps. You can also import multiple designs at once and choose the required specifications for each part.

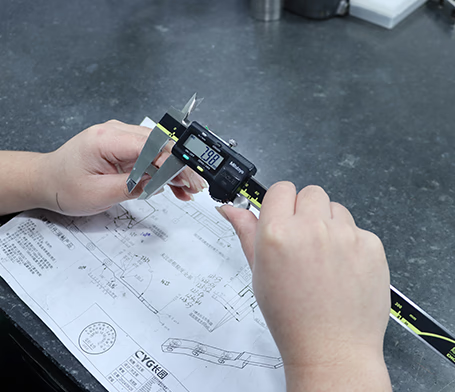

Tighter Tolerances

We machine aerospace parts to tight tolerances of +/-0.001 inches. We follow ISO 2768-m for metal and ISO-2768-c for plastics. Our capabilities also handle intricate designs for custom parts.

ISO9001 Certificated Quality

HYmoldplastic is ISO 9001 certified. Its production line uses advanced tech to ensure accurate, precise manufacturing. Each part has correct dimensions, structural strength and performance.

Solutions for Automotive Products

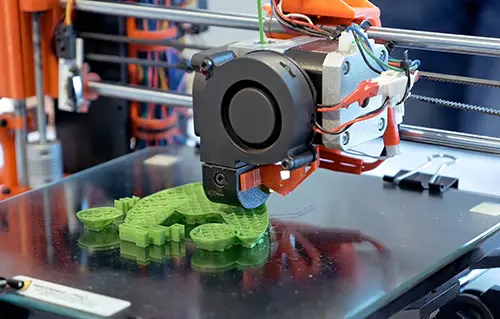

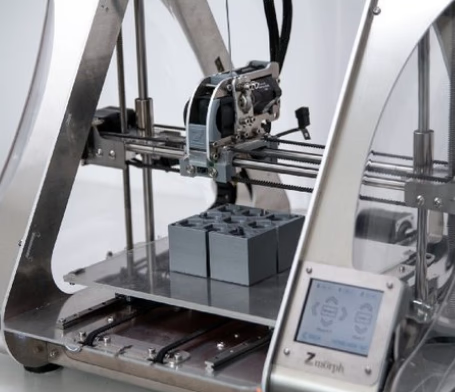

Prototype

Rapid turn-around times for early stage designs with a wide range of 3D printing technologies.

Rapid iterations on early stage designs

Detailed prototypes for complex geometry

Looks-like models

High-resolution functional prototypes

Production Verification Test

Rapid delivery of production level parts to validate manufacturing process

Production Tooling at low volumes

Tight tolerances on precision parts at bridge production quantities

Test fixtures to verify functionality and yield of production-ready parts

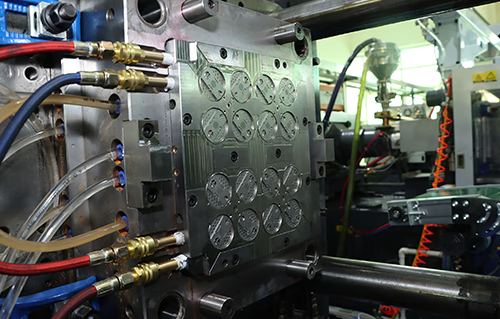

Mass production

Manufacturing line fixtures

Scale up to production level quantities quickly

Production tooling with multi-cavity and family tools

Materials for Automotive Components

Our manufacturing techniques are compatible with abundant materials to meet the industrial-grade demands of the automotive industry.

Materials

Best technologies

Benefits

Example parts

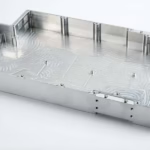

Aluminum

CNC machining, rapid tooling

Machinable, strong, range of grades

Cylinder heads, manifolds, Ductwork, housings, bus ducts

Steel

CNC machining, rapid tooling

Strong, corrosion-resistant, range of grades

Brake components, engine components

Titanium

CNC machining, SLM 3D printing

Lightweight, temperature-resistant

Engine valves, axle shafts, pipes, nuclear waste storage, pumps, turbines

PA(Nylon)

CNC machining, SLS 3D printing, injection molding

Strong, smooth surface finish

Peripheral engine parts, covers and housings

PMMA

CNC machining, injection molding

Transparent, shatter-resistant

Lighting components

Silicone

Liquid silicone injection molding

Durable, flexible, biocompatible, inert

Seals, cover assemblies, Fluid management devices, respiratory devices

Surface finishes for Automotive

Get high-quality surface finishing for your aerospace components to improve their corrosion and wear resistance.

Image

Name

Applicable Materials

Colors

Description

As Machined

Metals,Plastics

N/a

Anodizing

Metals

Clear, black, grey, red, blue, gold

Anodizing is a surface treatment for metal parts that improves corrosion resistance and surface hardness. It is widely used in industries such as aerospace, automotive, construction, electronics, and home furnishings.

Black oxide

Metals

N/a

Brushed

Metals

N/a

Bead Blast

Metals,Plastics

N/a

Powder Coating

Metals,Plastics

Applicable to all colors-Matt

Powder coat - Matt

Metals

Applicable to all colors-High gloss

Polishing

Metals

N/a

Electropolish

Metals

N/a

This process involves removing a material layer from a metal surface by electrochemical means. It improves smoothness and corrosion resistance. It’s mostly used on stainless steel.

Tumbling

Metals

N/a

Alodine

Metals

N/a

*Additional finishing options include chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. For materials not listed here, please contact us directly.

Manufacturing Applications in the Automotive Industry

- Lighting features and lenses

- Aftermarket parts

- Fixtures

- Housing and enclosures

- Armatures

- Assembly line components

- Support for vehicular consumer electronics

- Plastic dash components

Let’s Build Something Great, Together