Micro Molding Services

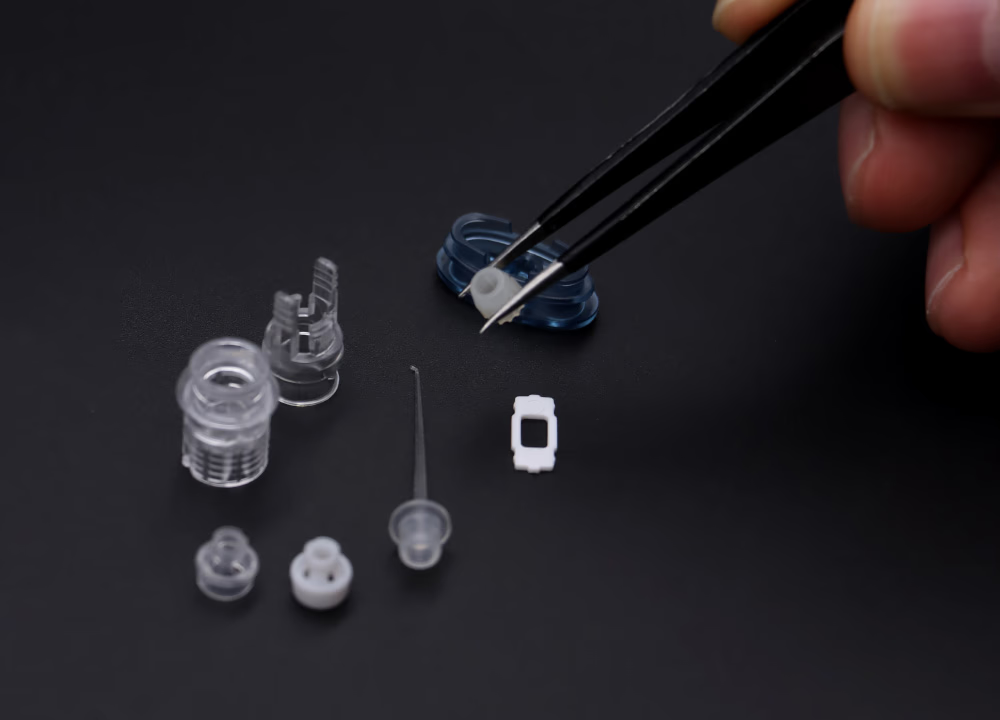

HYmoldplastic offers the highest quality micro molding services and can assist in the production of parts with intricate and complex geometries and excellent surface finishes.

Start Your Molding Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

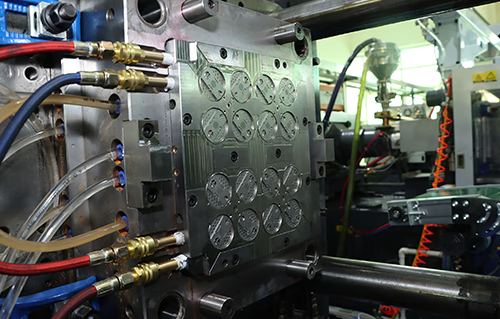

The Micro Injection Molding Process

Types of Micro Molding Processes

Insert Molding

Insert molding is a type of injection molding in which a metal component is placed into a mold cavity before molten plastic fills the mold. Insert molding is also possible with micro molding. In the insert micro molding process, a metal insert is positioned either manually or automatically by a robotic arm in the mold. Then, the mold closes, the plastic resin is injected in a single shot, and the molten plastic forms around the insert to create a single part. Finally, the part is ejected, the metal insert is removed, and the process repeats. Insert micro molding is a great way to enhance product durability and functionality. It is commonly used in the medical manufacturing industry to make components like catheters or in the electronics industry for micro-optic and integrated circuit components.

Overmolding

Material for Micro Molding

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

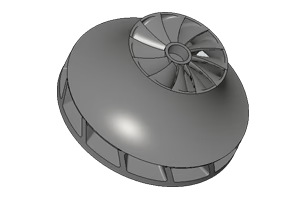

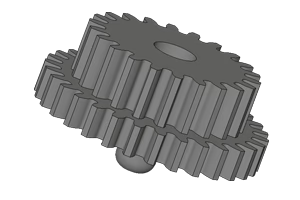

Delrin is DuPont’s trademarked polyoxymethylene (POM or acetal) resin. Delrin® is known for its strength, toughness, elasticity, rigidity, chemical and flame resistance, machinability, dimensional stability, and low friction coefficient. POM is used for mechanical components such as: gears, pulleys, and rollers.

Micro Molding Advantages

Lightweight

Micro molding creates parts that are lightweight and small. This is particularly useful for creating small and comfortable medical implants. Additionally, lightweight micro molded parts are also important in the creation of small, lightweight electronics or microfluidic components like small valves and fittings.

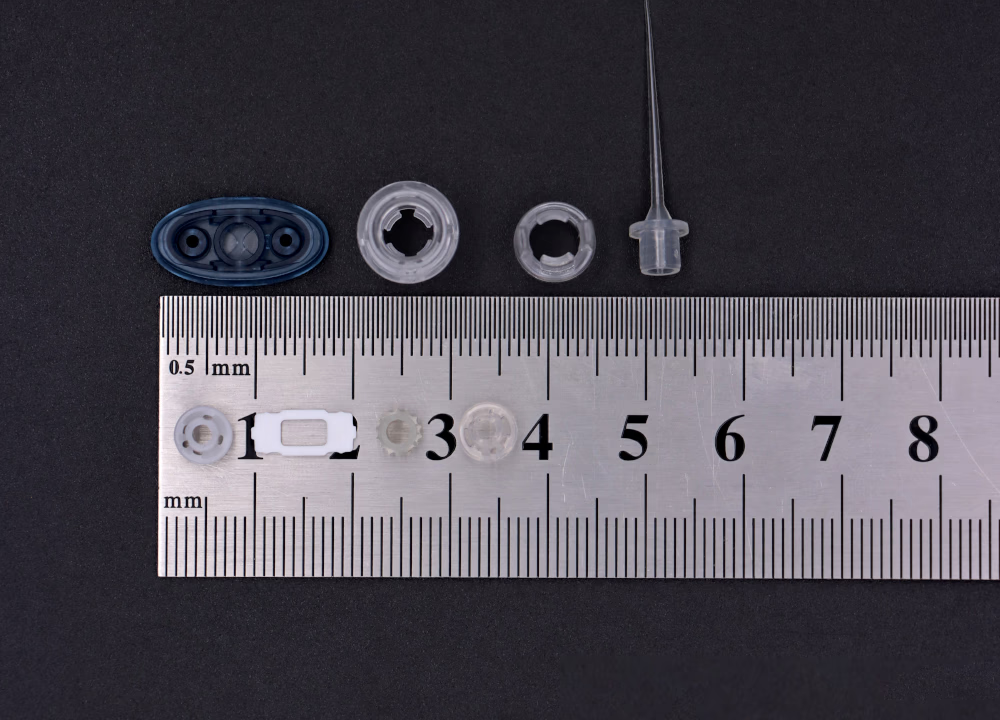

Size

Not only are the parts made by micro molding lightweight, but they are also exceptionally small in size. Advanced machining processes like micro-machining and EDM are used to create small, precise mold cavities and cores. As a result, micro-molded parts can easily fit into small and confined spaces. Micro molding has become a popular process for creating small parts in electronics, medical implants for orthopedics, pacemakers, and micro-optics.

Less Energy and Time

Micro molding offers significant cost savings compared to conventional injection molding. The cost savings are a result of the smaller tools and machinery needed to complete the micro molding process. Tools and molds are often smaller in size and thus cheaper to manufacture. Additionally, because parts are smaller, clamping forces are smaller, and consequently, power requirements are smaller. Finally, since parts are smaller, cycle times are often shorter since parts do not require as long a time to cool compared to parts made from conventional injection molding. All these traits of micro molding enable significant cost savings.

Tight Tolerances

Creating parts that satisfy tight tolerances is something the micro molding injection molding technique excels at. Micro molding enables the production of exceptionally small, detailed, and complex components with tolerances as small as 0.005” to 0.015”. Advanced manufacturing methods like micro-machining and EDM allow micro-sized cavities, cores, and other features to be made with great accuracy. The process is often used in the fabrication of electronics, medical devices, and micro-optics because of its ability to produce parts that satisfy tight tolerances.

Chemical Resistance

Thermoplastics used in the micro molding process often exhibit great chemical resistance. Therefore, the miniature parts created by the process can be used in applications with high exposure to various chemicals or in corrosive environments. This is particularly useful in the medical industry for implants, instruments, and diagnostic equipment, as well as in fluidic control components like valves and fittings. Additionally, various consumer goods and electronics may benefit from the chemical resistance offered by micro molded parts.

Micro Molding Applications

Let’s Build Something Great, Together