HP Multi Jet Fusion (MJF) 3D Printing Service

MJF 3D printing produces durable nylon parts for prototyping and production, offering complex geometries, smooth finishes, and strong mechanical properties. Parts can be obtained in as little as one day.

Start A New MJF Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

What is Multi Jet Fusion (MJF) 3D Printing?

Multi Jet Fusion (MJF) 3D printing, developed by HP, is a powder-bed technology that excels in manufacturing distinctive parts with superior surface finishes in a remarkably short time frame.

Multi Jet Fusion 3D Printing Capabilities

Our basic guidelines for Multi Jet Fusion include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Multi Jet Fusion Materials

PA 12 Black is a high tensile strength nylon. Final parts are dyed black, and they exhibit quality surface finishes and slightly more isotropic mechanical properties when compared to SLS. When more detail is required, PA 12 can achieve smaller minimum feature resolution (0.02 in) as compared to SLS materials (0.03 in). PA 12 Black is the best material option for designs that incorporate living hinges.

Primary Benefits

- Near isotropic mechanical properties

- Economical material choice

PA 12 40% Glass-Filled Black is a 40% glass-filled nylon. Final parts are dyed black. The biggest advantage offered by this material is heat deflection at 347°F (measured at 66 psi), ranking 2nd best after PA 12 Mineral-Filled.

Primary Benefits

- Economical material choice

- Heat deflection

Applications for HP MJF

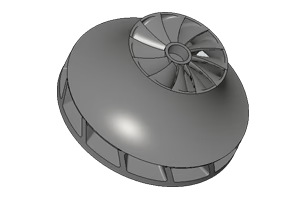

Concept Models

The speed and adaptability of MJF enable product developers to produce robust and intricate physical prototypes of their designs.

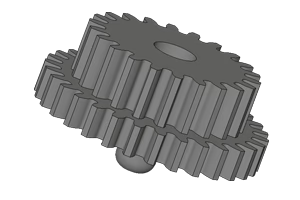

Rapid Prototyping

MJF technology enables the production of fully operational prototypes, including components with moving parts, and even complete assemblies in one go.

Direct Digital Manufacturing

The affordability and rapid production capabilities of Multi Jet Fusion make it an excellent choice for manufacturing large volumes of either standardized or tailored components.

Let’s Build Something Great, Together