Selective Laser Sintering (SLS) 3D Printing Service

High-quality prototypes and production parts available in just 1 day.

Start A New SLS Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

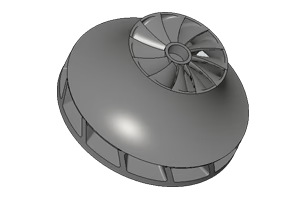

What is SLS 3D Printing?

Selective Laser Sintering (SLS) is an advanced 3D printing technique tailored for producing end-use components. In this method, a laser precisely fuses polymer powder particles, layer by layer, to construct parts. SLS creates functional plastic items with uniform mechanical properties, making

Selective Laser Sintering 3D Printing Capabilities

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Selective Laser Sintering (SLS) is an advanced 3D printing technique tailored for producing end-use components. In this method, a laser precisely fuses polymer powder particles, layer by layer, to construct parts. SLS creates functional plastic items with uniform mechanical properties, making

Selective Laser Sintering (SLS) Materials

PA 11 Black (PA 850) provides ductility and flexibility without sacrificing tensile strength and temperature resistance. These characteristics make PA 850 a widely used general-purpose material for functional and moving parts.

Primary Benefits

- Highest elongation at break of all additively manufactured nylons

- Uniform deep-black color that showcases features and provides a clean appearance

PA12 Black has all-around great mechanical properties and chemical resistance and is ideal for functional parts and prototypes.

Primary Benefits

- Highly isotropic mechanical properties

- Economical material choice

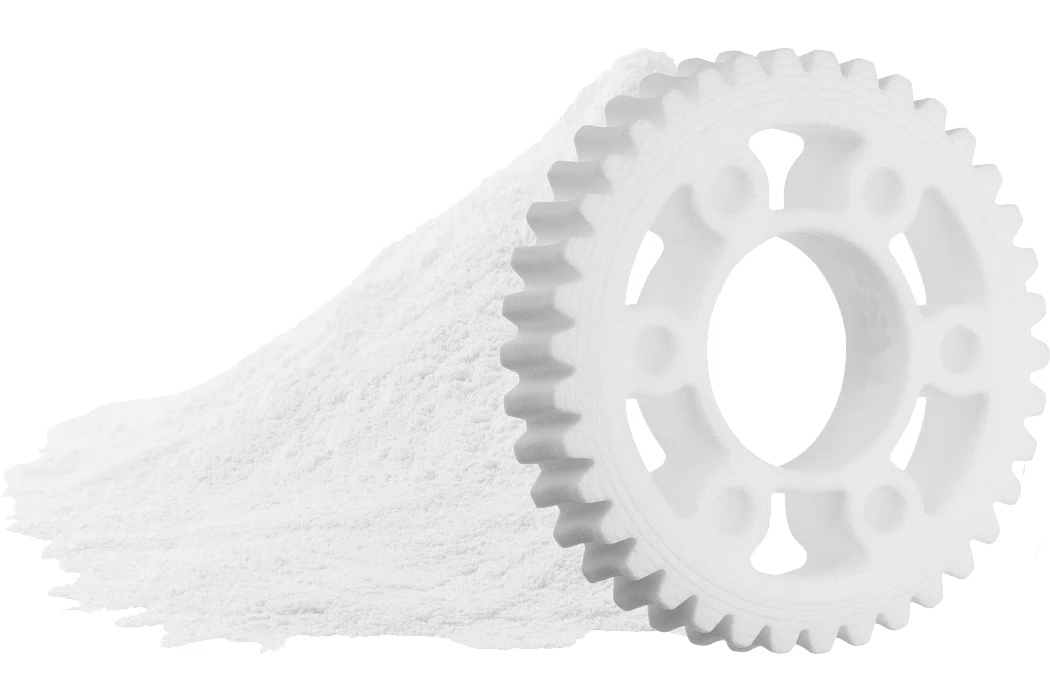

PA 12 White (PA 650) is a go-to material for general-purpose applications like functional and end-use parts. PA 650 is the strongest of the unfilled nylon materials and it is slightly stiffer than PA 11 Black.

Primary Benefits

- Economical material choice

- Strength and stiffness

PA12 Mineral-Filled (PA620-MF) is a 25% mineral fiber-filled PA powder. The fiber content significantly increases stiffness and HDT (up to 363 °F). It is a good material option when stiffness and high temperature resistance are important requirements.

Primary Benefits

- Highest stiffness of all additively manufactured nylons

- Temperature resistance

PA12 40% Glass-Filled (PA614-GS) is a PA powder loaded with glass spheres that make it stiff and dimensionally stable. This material is an ideal candidate for parts that require long term wear resistance properties. Due to the glass additive, it has decreased impact and tensile strengths compared to other nylons.

Primary Benefits

- Long-term wear resistance

- Increased stiffness

Polypropylene Natural offers chemical resistance properties that are top among the SLS and MJF material offerings. This tough and durable, yet flexible, material offers resistance to most acids and is a low weight material option.

Primary Benefits

- Chemical resistance

- Durable, low weight material

TPU 70-A is a white thermoplastic polyurethane that combines rubber-like elasticity and elongation with good abrasion and impact resistance properties. The rubber-like quality of this material make it ideal for seals, gaskets, grips, hoses, or any other application where excellent resistance under dynamic loading is required.

Primary Benefits

- High elongation at break

- Flexibility

SLS Finishes at HYmoldplastic

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Applications for Selective Laser Sintering

Concept Models

The speed and flexibility of SLS printing allow product developers to rapidly produce tangible representations of their designs during the iterative development process.

Rapid Prototyping

SLS prototyping enables the creation of fully operational prototypes, incorporating moving parts, and can also produce complete assemblies in a single process.

Direct Digital Manufacturing

The precision and reliability of Selective Laser Sintering (SLS) make it an optimal method for producing substantial quantities of either uniform or custom-designed parts.

Let’s Build Something Great, Together