Custom CNC Machining Services

Get instant CNC quotes for high-precision custom metal and plastic parts. Fast turnaround, tight tolerances, and delivery in as little as 3 days for prototypes and production runs.

Start A New CNC Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

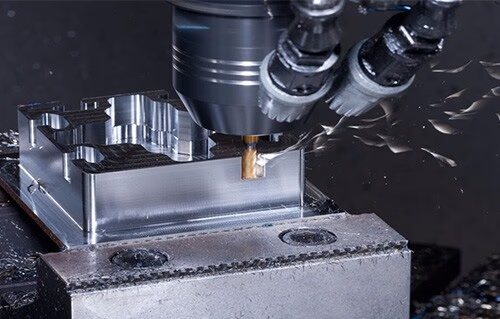

Our CNC Machining Service Capabilities

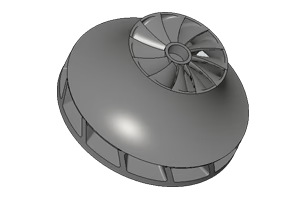

CNC Milling

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into final parts.

CNC Turning

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Electric Discharge Machining

Die-sinking EDM, wire EDM, and hole drilling EDM arie available, Fastest delivery time 3 working days

CNC Machining Materials

Online CNC machining services can deal with various materials, each having unique properties that make them well-suited for a broad range of materials.

CNC Metal

It is a light, non-reactive metal, hence a favorite option for aerospace and auto parts manufacturing.

Alloys

- Aluminum 6061, 6061-T6

- Aluminum 2024

- Aluminum 5052

- Aluminum 5083

- Aluminum 6063

- Aluminum 6082

- Aluminum 7075, 7075-T6

- Aluminum ADC12 (A380)

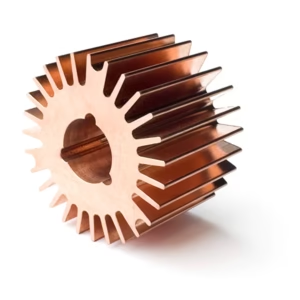

A metal with high electrical conductivity and flexibility that is commonly used for the composition of electric elements.

Alloys

- Copper C101(T2)

- Copper C103(T1)

- Copper C103(TU2)

- Copper C110(TU0)

- Beryllium Copper

Made by combining copper with zinc, brass is easy to shape into molds and pleasingly attractive.

Alloys

- Brass C27400

- Brass C28000

- Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

- Tin Bronze

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloys

- Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

- Die steel

- Alloy steel

- Chisel tool steel

- Spring steel

- High speed steel

- Cold rolled steel

- Bearing steel

- SPCC

Stainless steel offer excellent corrosion resistance, high strength, and good machinability, making them ideal for a wide range of applications in various industries.

Alloys

- Stainless Steel SUS201

- Stainless Steel SUS303

- Stainless Steel SUS 304

- Stainless Steel SUS316 / 316L

- Stainless Steel SUS420

- Stainless Steel SUS430

- Stainless Steel SUS431

- Stainless Steel SUS440C

- Stainless Steel SUS630/17-4PH

Very light, commonly found in aerospace or automotive applications.

Alloys

- Mangnesium Alloy AZ31B

- Mangnesium Alloy AZ91D

This element combines lightweight and high tensile strength and is hence utilized in aircraft construction alongside dental implants.

Alloys

- Titanium Alloy TA1

- Titanium Alloy TA2

- Titanium Alloy

- TC4/Ti-6AI 4V

CNC Plastics

Its strength, impact resistance, and ease of machining, making it suitable for prototypes, enclosures, and consumer products.

Subtypes

- ABS Beige(Natural)

- ABS Black ABS

- Black Antistatic

- ABS Milky White

- ABS+PC Black

- ABS+PC White

Their high strength, flexibility, excellent wear resistance, and low friction properties, making them ideal for producing durable and reliable parts.

Subtypes

- PA(Nylon) Blue

- PA6 (Nylon)+GF15 Black

- PA6 (Nylon)+GF30 Black

- PA66 (Nylon) Beige(Natural)

- PA66 (Nylon) Black

This plastic has excellent mechanical properties; thus, it is called high-performance plastic.

Subtypes

- PAI Brown

Polycarbonate (PC) is a durable, transparent thermoplastic used in CNC machining for its high impact resistance, optical clarity, and good dimensional stability, making it ideal for applications like protective covers, lenses, and medical devices.

Subtypes

- PC Black

- PC Transparent

- PC White

- PC Yellowish White

- PC+GF30 Black

PE (Polyethylene) materials for CNC machining are appreciated for their excellent chemical resistance, low moisture absorption, and high impact strength.

Subtypes

- PE Black

- PE White

Its strength, impact resistance, and ease of machining, making it suitable for prototypes, enclosures, and consumer products.

Subtypes

- ABS Beige(Natural)

- ABS Black ABS

- Black Antistatic

- ABS Milky White

- ABS+PC Black

- ABS+PC White

It is A hard and strong resin used predominantly for bottles and food containers.

Subtypes

- PET Black

- PET White

- PET+GF30 Black

- PET+GF30 White

Clear and resists weathering, often used for optical purposes.

Subtypes

- PMMA Black

- PMMA Transparent

- PMMA White

HDPE material is widely used for its high strength, impact resistance, chemical resistance, and ease of machining.

Subtypes

- HDPE Black

- HDPE White

HIPS (High Impact Polystyrene) is an impact-resistant, cost-effective thermoplastic used in packaging, consumer products, and automotive components.

Subtypes

- HDPE Black

Polyformaldehyde (POM) has the characteristics of high stiffness, low friction, good dimensional stability, good wear resistance and so on.

Subtypes

- Dark brown (coffee) POM 100AF

- POM Black

- POM Blue

- POM White

PP has good chemical resistance; at room temperatures, PP can be flexible.

Subtypes

- PP Black

- PP White

- PP+GF30 Black

For Example: High Performance Plastics, Engineering Plastics, Industrial Plastics, Biocompatible Materials, Food Safe Plastics, and Other Modified Thermoplastics.

Custom Sourced Materials

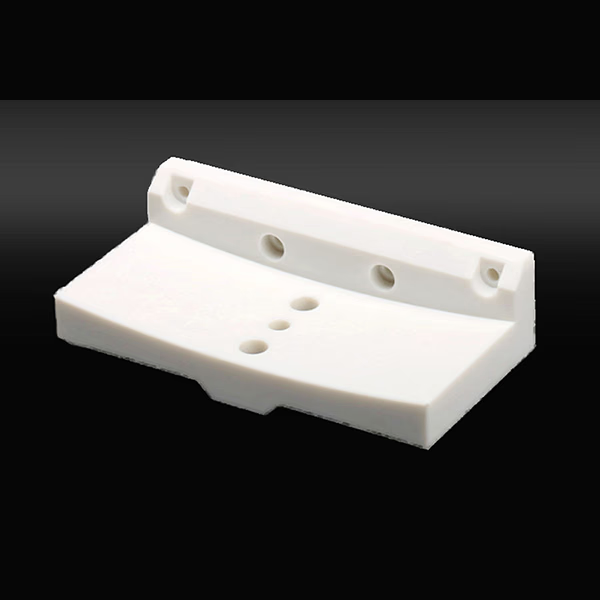

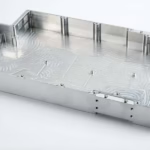

Finishing Options for CNC Machining

Image

Name

Applicable Materials

Colors

Description

As Machined

Metals,Plastics

N/a

Anodizing

Metals

Clear, black, grey, red, blue, gold

Anodizing is a surface treatment for metal parts that improves corrosion resistance and surface hardness. It is widely used in industries such as aerospace, automotive, construction, electronics, and home furnishings.

Black oxide

Metals

N/a

Brushed

Metals

N/a

Bead Blast

Metals,Plastics

N/a

Powder Coating

Metals,Plastics

Applicable to all colors-Matt

Powder coat - Matt

Metals

Applicable to all colors-High gloss

Polishing

Metals

N/a

Electropolish

Metals

N/a

This process involves removing a material layer from a metal surface by electrochemical means. It improves smoothness and corrosion resistance. It’s mostly used on stainless steel.

Tumbling

Metals

N/a

Alodine

Metals

N/a

*Additional finishing options include chromic acid anodizing, cadmium plating, copper plating, titanium anodizing (blue anodizing), gold plating, silver plating, and more. For materials not listed here, please contact us directly.

CNC Machining Capabilites

Feature | Description |

General Tolerances | Metals: +/- 0.005“(+/- 0.127 mm) Plastics: +/- 0.010”(+/- 0.254 mm) |

Precision Machining Tolerances | ±0.0004″ (0.01mm) |

Min Wall Thickness | 0.5mm |

Maximum Part Size | CNC Milling: 4000×1500×600 mm CNC Turning: 200×500 mm |

Minimum Part Size | CNC Milling: 5×5 ×5 mm CNC Turning: 2×2 mm |

Surface Finish (As Machined) | 125 Ra or better |

Lead Time | 1-5 Working Days |

Multi-industry applications of CNC machining services

We’ve manufactured millions of parts for a wide range of applications, with specialized expertise in such as automotive, medical devices, electronics, consumer products, etc.]. Our deep knowledge in these sectors allows us to deliver high-quality, tailored solutions for every project.

Aerospace

Precision manufacturing boosts aerospace development.

Automotive

Automotive grade certified precision parts.

Consumer Products

First choice for new product launches

Medical

Medical grade certified precision parts

Robotics

Accelerate the development of the future robotics industny

Advantages of CNC Machining

The subtractive process of CNC machining provides multiple benefits for both prototyping and production parts.

- Housings and enclosures

- Brackets

- Fixtures for manufacturing

- Gears and bearings

- Internal mechanical components

- Medical instrumentation

CNC Machining Applications

CNC machining is widely used throughout the aerospace, medical, automotive industries for its ability to rapidly manufacture precise parts in production-grade materials. Typical CNC parts, include:

- Housings and enclosures

- Brackets

- Fixtures for manufacturing

- Gears and bearings

- Internal mechanical components

- Medical instrumentation

CNC Machining FAQs

What are the applications of CNC machining?

CNC machining has a wide range of applications across industries.

In the automotive and aerospace sectors, it is used to fabricate precise engine components, structural parts, and other intricate elements.

The medical industry leverages CNC for manufacturing devices, implants, and surgical instruments.

CNC is also crucial in electronics, enabling the production of electronic housings, circuit boards, and connectors.

Machine tool makers rely on CNC to create complex molds, dies, and machine components. Additionally,

CNC is valuable for general custom part production, prototyping, woodworking, and more, allowing for consistent quality and high precision.

What are the advantages and disadvantages of CNC machining?

Advantages of CNC Machining

Precision and Repeatability: CNC machining ensures high precision and consistent replication of parts, crucial for complex designs with tight tolerances.

Reduced Human Error: The automated nature of CNC machining minimizes human error, enhancing the overall quality of production.

Efficiency and Speed: Automation allows for faster production cycles, enabling quicker turnaround times than manual processes.

Material Flexibility: CNC machines can work with a diverse range of materials, including metals, plastics, and composites, offering versatility across various applications.

Software Integration: Advanced CNC software supports quick design changes and updates, facilitating rapid prototyping and easy customization.

Cost-Effective for Large Runs: While setup costs are higher, per-unit costs decrease significantly with larger production volumes, making it cost-effective for mass production.

Disadvantages of CNC Machining

High Initial Costs: CNC machinery and its maintenance represent significant investments, making initial setup expensive, especially for small-scale operations.

Skill Requirements: Operating CNC machines requires highly skilled personnel, which can increase training costs and limit accessibility.

Less Cost-Effective for Small Runs: Due to setup and programming time, CNC machining may not be economical for producing small quantities of parts.

Material Waste: CNC machining often involves subtractive processes, leading to more material waste compared to additive manufacturing.

Limited to Material Hardness: Extremely hard materials can wear out CNC tools quickly, potentially increasing operational costs and downtime.

What's the difference between 3D printing and CNC machining?

Manufacturing Process: 3D printing is an additive process, building parts layer by layer from materials like plastic or metal. In contrast, CNC machining is subtractive, cutting away material from a solid block to shape the final product.

Material Efficiency: 3D printing minimizes waste by using only the material needed to form the part, whereas CNC machining can produce more waste due to its subtractive nature.

Speed and Cost: For small batches and complex geometries, 3D printing can be faster and more cost-effective. CNC machining is preferable for larger volumes and materials requiring high precision and strength.

Surface Finish and Tolerances: CNC machining typically achieves better surface finishes and tighter tolerances compared to 3D printing.

Who is the father of CNC machining?

John T. Parsons is often credited as the father of CNC machining. In the late 1940s, Parsons developed the first numerical control techniques and applied them to the production of helicopter rotor blades. Working alongside engineer Frank L. Stulen, Parsons conceptualized the method of using punched tape to guide machine tools. This innovation laid the groundwork for the development of CNC (Computer Numerical Control) technology. Their pioneering work eventually led to the creation of the first CNC machines in the 1950s, which revolutionized manufacturing by improving the precision, efficiency, and repeatability of machining processes.

What is the G and M code in CNC machines?

What tolerances could CNC machining reach?

CNC machining is renowned for its ability to achieve high precision and tight tolerances, essential for complex and detailed parts. Typically, standard CNC machining can maintain tolerances within ±0.01 inches (±0.127 mm). HYmoldplastic defaults to standardized tolerances without special requirements. For even more precise requirements, advanced CNC machines can achieve tolerances as tight as ±0.0005 inches (±0.0127 mm) under optimal conditions. The achievable tolerance depends on several factors including the material, part geometry, size, and the specific type of CNC machine used. This capability makes CNC machining a preferred choice for industries that require highly accurate components, such as aerospace, medical, and automotive sectors.

What is machining center and how does it work?

Can you provide insight into your CNC machining capacity?

How much does your CNC machining service cost?

Is there a minimum order quantity (MOQ) for CNC machining at HYmoldplastic?

How long does it take to receive a part once an order is placed?

The lead time for receiving a CNC machined part from HYmoldplastic can vary depending on several factors including the complexity of the part’s design, the type of material selected, and our current production schedule. CNC machining is known for its speed, particularly for less complex parts, allowing for quick turnaround times. In fact, parts can be delivered in as fast as just one day after the machining setup is complete! However, for the most accurate time estimate tailored to your specific project, we recommend contacting us directly for a detailed quote. This way, we can provide you with a precise timeframe based on your unique requirements.

Let’s Build Something Great, Together