Custom Insert Molding Service

Start A New Molding Inserts Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

Plastic Molding Capabilities

Our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall production time.

| US | Metric | |

| SIZE | 18.9 in. x 29.6 in. x 8 in. | 480mm x 751mm x 203mm |

| VOLUME | 59 cu. in. | 966,837 cu. mm |

| DEPTH | 4 in. from parting line | 101mm from parting line |

| Up to 8 in. if parting line can pass through the middle of the part | Up to 203.2mm if the parting line can pass through the middle of the part | |

| PROJECTED MOLD AREA | 175 sq. in. | 112,903 sq. mm |

Tolerances: Typically, HYmoldplastic can maintain a machining tolerance of +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm).

Insert Molding Finishing Options

Range of finishes from Grade 3 diamond / high polish to 320 stone low polish. Finishes include: SPI A-1 SPI A-2 SPI A-3 SPI B-1 SPI B-2 SPI B-3 SPI C-1 SPI C-2 SPI C-3 SPI D-1 SPI D-2 SPI D-3

No secondary polishing or grinding. Part will show tooling marks.

HYmoldplastic can match other mold textures upon request.

Engraving text or a design with a laser.

Thermoplastic Materials

We have wide selection of more than 100 thermoplastic and thermoset materials.

- ABS

- ABS/PC

- Acetal

- POM

- ETPU

- HDPE

- LCP

- LDPE

- LLDPE

- Nylon

- PBT

- PC/PBT

- PEEK

- PEI

- PET

- PETG

- PMMA (Acrylic, Plexiglas)

- Polycarbonate

- Polypropylene

- PPA

- PPE/PS

- PS

- PSU

- TPU

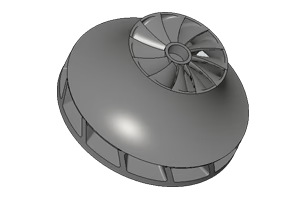

What is Plastic Injection Molding?

Injection molding is a manufacturing process that involves filling a metal mold cavity with liquid plastic resin, which cools and solidifies into a plastic part.

This method is commonly used for high-volume production due to its low material waste and cost per part. It’s ideal for industries such as medical devices, consumer products, and automotive.

Our plastic injection molding process produces custom prototypes and end-use production parts with lead times as fast as one day. We utilize aluminum molds for cost-efficient tooling and accelerated manufacturing cycles, and we stock around 200 different thermoplastic resins.

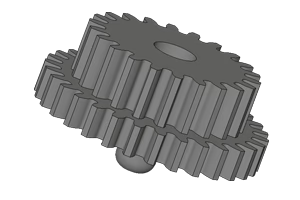

Applications of Plastic Insert Molding

Automotive

Automotive grade certified precision parts.

Consumer Products

First choice for new product launches

Medical

Medical grade certified precision parts

Let’s Build Something Great, Together