Production Tooling Making Service

- A comprehensive service provider of injection molds and stamping molds.

- Get your high quality production tooling in 7 days

- Regularly show you our production progress in pictures or videos

Start A New Mould Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

- All uploads are secure and confidential.

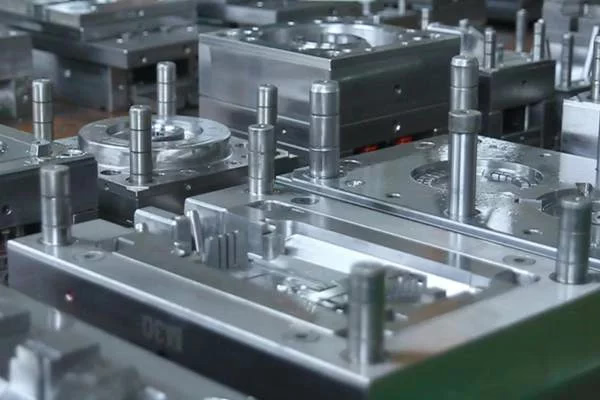

Mold Fabrication

Production Solutions For You

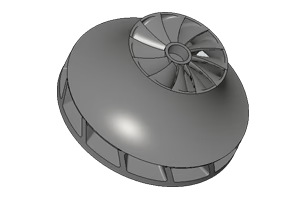

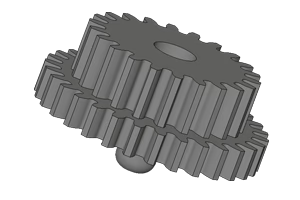

Once the rapid tooling phase is complete, your product will move on to mass production, and that’s where our production tooling services come in handy. Injection molding, forging molding, stamping and other types of molds are the products of our production mold services.

HYmoldplastic’s production tooling service has been cultivated in this industry for many years, representing the level of Chinese industrial manufacturing, and has been widely praised by our customers.

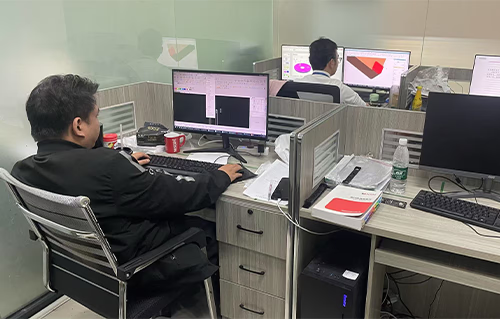

Mold Design

- Designer Staffs: 8. Monthly design of 28 sets of molds;

- Advanced design concepts and services, including automatic design, automatic programming and in-line inspection.

- Application software contains: UG, AUTO-CAD, CATIA , MOLDFLOW

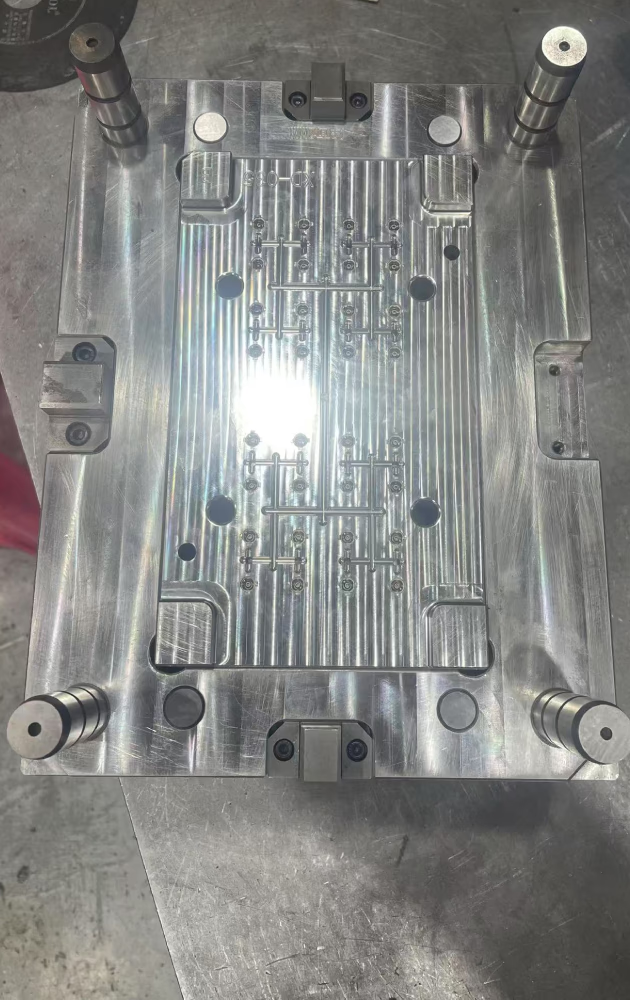

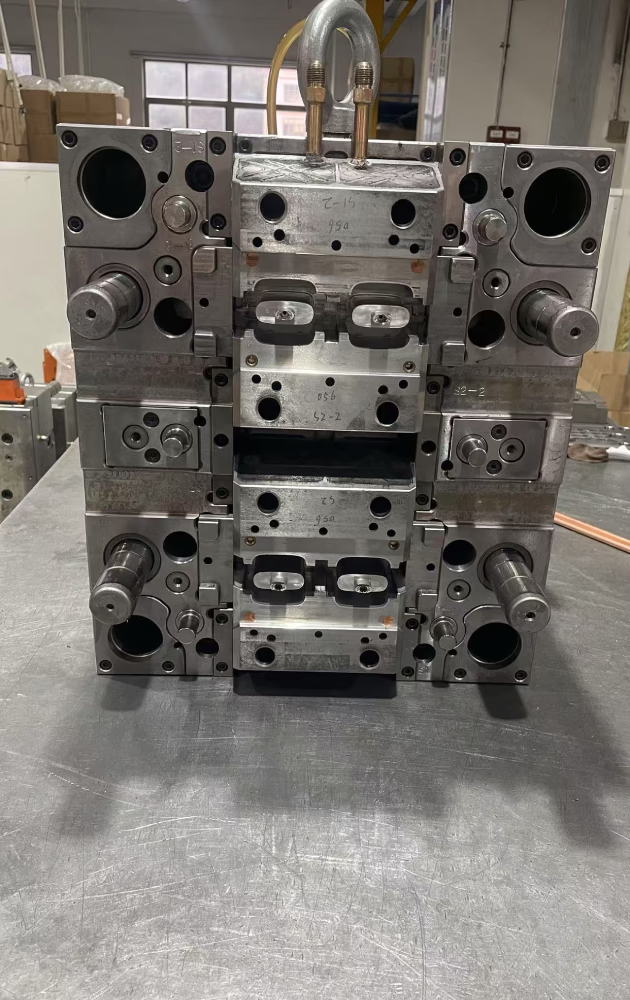

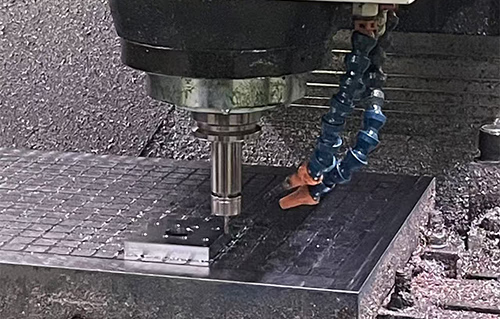

Mold Making

- World-class equipment and superior precision

- World-class equipment and superior precision

- The introduction of automated processing has greatly increased production capacity and efficiency.

- Monthly mold making: 20 sets

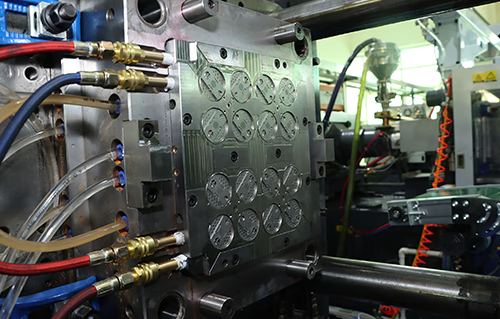

Mass Production

- Equipment models: from 90 tonage to 1000 tonage

- Advanced equipment and perfect management system in the industry

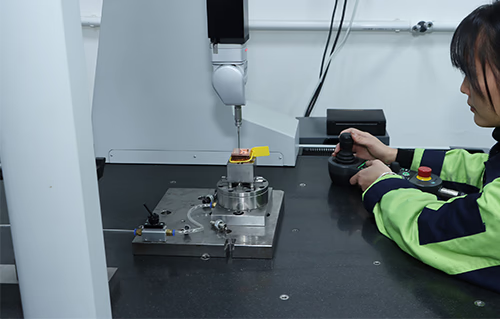

Quality Control

- ISO9001:2016 system, IATF 16949 for the automotive industry

- IPQC reduces the error rate and waste during mould processing.

- Quality control ensures that the final product meets the requirements and expectations of the customer.

- Special product arrangements for full inspection.

Common Types of Rapid Tooling

We offer various types of mold tooling, depending on your specifications and applications. From prototype mold tooling to production and export molds, HYmoldplastic is your reliable partner.

Aluminum Mold Tooling

This is the ideal choice for prototype injection molding because it is a cost-effective means of producing injection molded parts. Using aluminum ensures dimensional stability in the mold tooling, significantly reducing waste production and part deformation during production. Aluminum molds are also easier to cut, thereby reducing tooling costs by up to 25%. Using aluminum molds also reduces cycle times by 30-40%. All of these combine to ensure faster turnarounds.

Steel Mold Tooling

Steel is a high-quality, solid, and sturdy material with a longer life cycle. It is more suitable for high-volume production runs and for producing molds from engineering-grade plastics. Despite its long life cycle, it is more expensive than aluminum and may require more time to produce mold tooling and prototypes.

Rapid Tooling & Prototype Injection Molding Services

Molds tailored to your needs.

We provide in – depth guidance to help you choose the most suitable mold for your specific project requirements.

|

SPI Finish Grade

|

General Mold Material

|

Estimated Usage Times (Approximate)

|

|

A-1

|

High – quality tool steel (e.g., P20, H13)

|

500,000 – 1,000,000 cycles

|

|

A-2

|

Good – quality tool steel (e.g., P20, modified alloy steel)

|

300,000 – 800,000 cycles

|

|

B-1

|

General – purpose tool steel (e.g., standard alloy steel)

|

200,000 – 600,000 cycles

|

|

B-2

|

Medium – grade alloy steel

|

100,000 – 400,000 cycles

|

|

C-1

|

Low – cost alloy steel or some cast iron materials (if applicable)

|

50,000 – 200,000 cycles

|

Experts in Tool Design

Design for Manufacturing (DFM) in tooling focuses on optimizing mold designs to enhance the efficiency and quality of the injection molding process. By considering factors such as ejection and cooling, gate placement, mold flow analysis, draft angles, and part consolidation, we ensure the tooling is tailored to produce high-quality parts with minimal defects. Our DFM expertise reduces cycle times, improves product durability, and minimizes production costs, ensuring an efficient and cost-effective manufacturing process.

Ejection and Cooling Considerations

Plan for Ejection: Ensure the design includes features that facilitate easy ejection, such as ejector pin locations. For example, flat surfaces for ejector pins to push against on the base of a complex component.

Efficient Cooling: Design parts to allow for effective cooling within the mold to reduce cycle times and improve quality. For example, designing a part with consistent wall thickness allows for uniform cooling.

Gate Placement

Mold Flow Analysis

Conduct Mold Flow Analysis: Use simulation software to predict the flow of molten plastic, identify potential issues like air traps, weld lines, or hotspots, and adjust the design accordingly. For example, simulating the injection molding process for a car dashboard can help optimize gate locations and cooling channels.

Draft Angles

Include Appropriate Draft: Adding a draft angle (typically 1-2 degrees) on the walls of the part allows it to be easily ejected from the mold. For instance, a plastic cup should have slight tapering walls to facilitate ejection.

Part Consolidation

Let’s Build Something Great, Together